HANDS -ON TRAINING AND PROFESSIONAL COURSES

At IONICS, we offer a wide range of professional condition monitoring and reliability training programs designed to bridge theory and real industrial practice. Our training includes extensive hands-on sessions with live demonstration kits that simulate real machine faults, allowing participants to detect, diagnose, correct the fault, and immediately observe the results. Trainees work with industry-proven machine analyzers such as the CSI 2130, gaining practical experience in vibration measurement, fault diagnosis, and corrective actions. In addition to hands-on training, our professional courses include rich industrial case studies drawn from real operating environments, enabling participants to apply best practices, improve diagnostic confidence, and enhance machinery reliability and performance.

HANDS-ON | VIBRATION ANALYSIS

This intensive hands-on Vibration Analysis training provides participants with a complete understanding of vibration fundamentals, including what vibration is, how vibration signals behave, the different types of sensors, and the essential principles of signal processing. The course guides learners through machine fault diagnosis using spectrum analysis while offering extensive practical sessions such as data collection on test rigs, acquiring data with multi-resolution lines and multi-number averages, and performing advanced measurements like Fmax/Fmin analysis. Participants will learn to diagnose common machine faults—including unbalance, misalignment, and looseness—through real-world exercises involving cross-phase measurements, bump tests, turning-speed detection, and live-mode analysis.

HANDS-ON | LASER ALIGNMENT

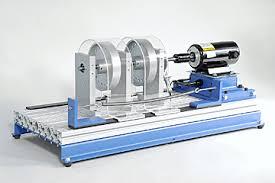

HANDS-ON | IN SITU BALANCING

This hands-on balancing course provides a complete understanding of rotating machinery unbalance, including what unbalance is, its different types, and how to determine unbalance severity. Participants learn how unbalance affects rotating equipment and how to diagnose faults using vibration analysis with a strong emphasis on the importance of phase measurement. The course covers the differences between rigid and flexible rotors, and provides practical training on correcting unbalance using both rigid rotor and high-speed balancing machines, as well as field balancing techniques. A major part of the program focuses on real-world exercises, including hands-on balancing using a dedicated test rig to reinforce practical skill development.

TRAINING COURSE | VIBRATION ANALYSIS & MACHINE FAULT DIAGNOSIS ( CAT I + CAT II)

This course provides a complete foundation in vibration analysis and machine fault diagnosis. Participants learn the essentials of maintenance strategies, condition monitoring, and vibration fundamentals, including vibration behavior, frequency interpretation, time-waveform analysis, and spectrum analysis. The course covers how to measure vibration correctly, select the right transducers, and mount sensors for accurate data collection.You will develop strong diagnostic skills to identify common machinery faults such as misalignment, unbalance, looseness, bent shafts, bearing defects, gear problems, journal bearing issues, and soft foot. The curriculum also includes advanced analysis techniques such as resonance detection, phase analysis, run-up and coast-down testing, and diagnosing faults under variable-speed conditions. By the end of the program, attendees can confidently interpret vibration signatures and apply appropriate corrective and predictive maintenance actions.

TRAINING COURSE | INTRODUCTION TO SHAFT ALIGNMENT

This course provides a complete introduction to shaft alignment, emphasizing why proper alignment is essential for preventing bearing damage, seal failures, coupling wear, vibration, energy losses, and unplanned downtime. Participants gain a thorough understanding of misalignment types, shaft fatigue, offset and angular errors, alignment conventions, tolerance specifications, and the behavior of rotating machinery. Pre-alignment procedures are covered in detail, including determining the alignment state, straightedge and feeler gauge techniques, dial indicator methods, rim-and-face measurement, reverse-dial approaches, and managing soft foot conditions. The course also introduces laser alignment systems, teaching how to position sensors, move the machine vertically and laterally, interpret readings, and perform precise alignment using modern laser tools. Through practical exercises, attendees develop the skills to achieve accurate shaft alignment that improves machine life, reliability, and performance.

TRAINING COURSE | PUMPS TECHNOLOGY

This course provides a practical introduction to pump technology, covering both centrifugal pumps and positive displacement pumps. Participants learn pump operating principles, pump classifications, hydraulic fundamentals, and the differences between volute, diffuser, mixed-flow, axial-flow, and multi-stage pump designs. The course also explores key mechanical components—including impellers, casings, shafts, seals, sleeves, wear rings, and bearings—along with gear, lobe, vane, screw, reciprocating, piston, and plunger pump types. Additional topics include pump performance characteristics, couplings, safety valves, accumulators, and essential maintenance and troubleshooting practices to improve pump efficiency and reliability.

TRAINING COURSE | BEARINGS FUNDAMENTALS

The Bearing Fundamentals course provides a practical understanding of rolling element bearings used in rotating machinery. It covers bearing types, designations, internal clearances, fits and tolerances, lubrication principles, mounting and dismounting techniques, and common failure modes. Participants will learn how operating conditions, lubrication selection, contamination, and installation practices affect bearing life, reliability, and machine performance, with real-world examples and preventive maintenance best practices.

TRAINING COURSE | MECHANICAL SEALS FUNDAMENTALS

The Shaft Sealing Fundamentals course provides a comprehensive introduction to sealing technologies used in rotating equipment. It covers mechanical seal principles, packed stuffing boxes, seal face lubrication, basic and advanced seal designs, API seal types, and common seal arrangements including single, double, tandem, cartridge, split, and dry gas seals. Participants will gain practical understanding of seal selection, installation, operation, flushing systems (API plans), environmental controls, and troubleshooting techniques, with emphasis on improving reliability, reducing leakage, and preventing seal failures in industrial applications.